What Is a Purchase Order? A Simple Guide for Product Businesses

Contents

When your team needs to purchase goods or services, a casual email or phone call isn’t enough. Product-based businesses rely on structure, traceability, and control — and that’s exactly what a purchase order provides.

If you’ve ever dealt with stock issues, over-ordering, or disputes with suppliers, this guide is for you.

We’ll walk through the entire purchase order process, from creation to payment, and explain why purchase orders play such a critical role in operations for manufacturers, retailers, and food & beverage (F&B) businesses.

What Is a Purchase Order?

A purchase order (PO) is a legal document sent by a buyer to a supplier to formally request specific goods or services, including quantities, agreed prices, and delivery dates. Once a vendor accepts the PO, it becomes a legally binding agreement.

In Australia and New Zealand, as in most countries, a purchase order is part of the procurement process — used to manage business purchases efficiently and with legal protection.

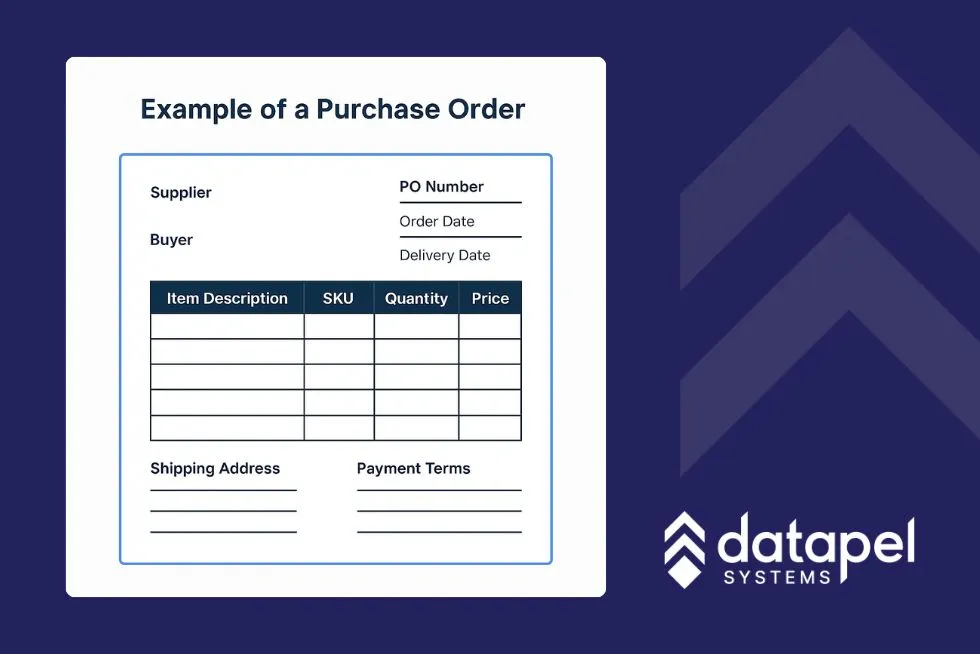

What Does a Purchase Order Include?

A standard purchase order form typically contains:

- Buyer and supplier details

- Unique purchase order number (PO number)

- Order date (purchase order date)

- Delivery times and tentative delivery dates

- Description of goods or services

- Quantity and agreed prices

- Payment terms and applicable discounts

- Shipping address

- Packing slip reference

These purchase order details are crucial to ensure accuracy and accountability throughout the purchasing process.

Purchase Order vs Invoice: What’s the Difference?

Understanding purchase order vs invoice helps clarify each step in the buying process:

| Purchase Order (PO) | Invoice |

|---|---|

| Created by buyer | Created by supplier |

| Sent before goods are delivered | Sent after goods are delivered |

| Requests goods or services | Requests payment |

| Acts as a legally binding contract | Acts as a billing statement |

Once the supplier sends an invoice, the buyer pays based on the confirmed PO and received goods.

What Is the Purchase Order Process?

The purchase order process is a series of steps from purchase requisition to payment:

1. Purchase Requisition

A team member initiates a purchase order request, identifying the need for goods. This may be reviewed by the purchasing department or procurement manager.

2. Purchase Order Creation

Once approved, the team begins creating a purchase order, manually or via an automated PO system. This reduces errors and speeds up the process.

3. Supplier Confirmation

The supplier accepts the PO and confirms quantities, prices, and delivery dates.

4. Delivery and Receipt

The goods are delivered as per the specified timeframe. The delivery is checked against the PO and recorded via a packing slip.

5. Invoice Matching and Payment

The supplier sends an invoice. The accounts payable team matches the invoice with the PO and delivery record. Once verified, the buyer pays.

This entire purchase order process ensures transparency, legal clarity, and control.

What Is a Purchase Requisition?

A purchase requisition is an internal request to buy something. It precedes a PO and is often submitted by staff, then reviewed by the purchasing manager or procurement department.

It ensures spending is controlled and authorised before a formal purchase order form is created.

Common Purchase Order Types

Here are four common types of POs used in Australian businesses:

1. Standard Purchase Order

One-time orders with fixed quantities, prices, and delivery dates.

2. Blanket Purchase Order / Blanket Purchase

Used for ongoing orders over time with a single supplier. Ideal for businesses managing multiple deliveries under the same contract. Also called a blanket PO.

3. Planned Purchase Order

Similar to blanket POs but with tentative delivery schedules.

4. Contract Purchase

A formal agreement for future orders based on agreed upon terms.

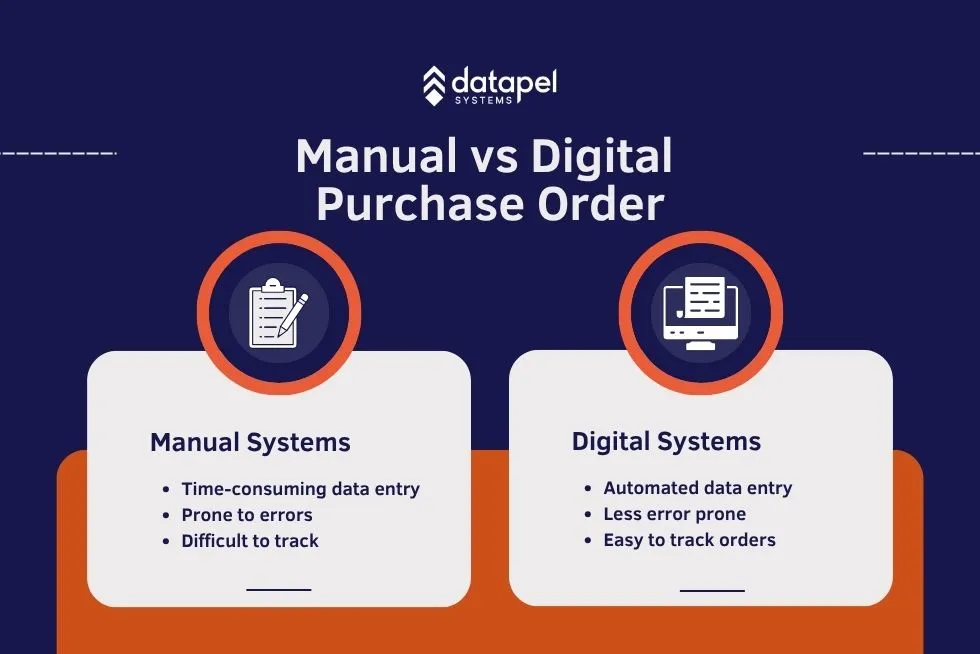

Digital Purchase Orders vs Manual Systems

Manual systems like spreadsheets or paper forms are prone to errors. Digital purchase orders eliminate duplication, speed up approvals, and integrate with your inventory management system, ERP system, or accounting software.

Benefits of electronic purchase orders:

- Faster purchase order creation

- Easier tracking of purchase orders

- Better visibility into pending orders and incoming orders

- Automated workflows for the purchasing department

If you’re managing growing volumes, an automated system or full PO system is worth the investment.

The Benefits of Inventory Management Systems for Purchase Orders

If you’re running a product business, managing purchase orders effectively isn’t just a nice-to-have — it’s essential for keeping your inventory, operations, and finances in sync. That’s where an inventory management system like Datapel Cloud.WMS comes into play.

1. Create POs Directly from Sales Orders

Instead of manually re-entering details, Datapel lets you generate a purchase order straight from a sales order. It’s quick, reduces errors, and ensures what you’re buying directly matches what you need to fulfil.

2. See the Right Info, Fast

Users appreciate how easy it is to find key PO details without jumping between screens. A simple, intuitive layout means less time training new staff and fewer mistakes across your purchasing process.

3. Integrated with Accounting

Datapel syncs purchase and sales orders with your accounting software. This keeps your inventory and financials aligned — no more manual reconciliation, and no surprises at month-end.

4. Handles Complex Requirements

Whether you’re exporting manufactured goods or dealing with customer-specific labels, Datapel adapts. For one manufacturer, automated documentation in the PO workflow saved time and reduced compliance risk.

5. Custom Reporting That Works for You

Datapel links with Excel templates so you can generate consistent reports — great for supplier communication or head office updates. No more manual formatting. For more information or to get in touch, contact us.

6. No Disruption During Set-up

Implementation is smooth. Businesses have reported zero downtime when switching to Datapel, meaning you get better purchase order control without interrupting day-to-day operations.

“We’ve used Datapel for over five years. It’s easy to use and makes warehouse tasks like managing bin locations much simpler. Being able to create purchase orders directly from sales orders has saved us a lot of time.”

— Louise Miller, Frost Group

For growing teams ready to move beyond spreadsheets, this type of system adds accuracy, traceability, and efficiency at every step.

Why Purchase Orders Matter for Product Businesses

In retail, F&B, and manufacturing, managing purchase orders is key to keeping operations running smoothly. Here’s what purchase orders play a role in:

- Preventing stockouts and overstocking

- Reducing supplier disputes

- Improving forecast accuracy

- Ensuring legal clarity with a legally binding and auditable trail

Purchase Order Financing: How Does It Work?

If cash flow is tight, PO financing allows businesses to pay suppliers before receiving customer payment. With purchase order financing, a third-party finances the order on your behalf. Useful for large or unexpected orders.

FAQs About Purchase Orders

What is meant by purchase order?

A purchase order is a formal legal document from a buyer to a supplier requesting goods, including specific terms and pricing.

What is a PO vs. invoice?

A PO initiates a purchase; an invoice requests payment. The purchase order vs invoice distinction is key for tracking and compliance.

How does a PO get paid?

Once goods are delivered and the invoice matches the PO, the accounts payable team processes payment.

What’s the difference between PR and PO?

A purchase requisition (PR) is an internal request; a purchase order is the external, approved document sent to a supplier.

What is a purchase order in Australia?

In Australia, a purchase order functions as a legally binding agreement used across industries to manage commercial purchases with clarity and protection.

Start Using Purchase Orders Today

Whether you’re ordering raw materials, stock for retail, or ingredients for production, a proper purchase order system ensures everything is traceable and secure.

Ready to take the manual work out of purchasing?

Book a demo with one of our experts to see if Datapel is the right fit for your business.

As a WMS Industry Analyst & Content Lead I write about warehouse management systems from real experience—helping businesses streamline operations, reduce errors, and scale smarter.

Over the past 8 years, I’ve worked closely with warehouse teams, tech developers, and business owners to break down complex supply chain problems into actionable solutions. My goal? Make WMS content useful, not just informative.

When I’m not writing, I’m digging into user feedback, testing new tools, or speaking with industry experts to stay ahead of what matters most to warehouse operators.