Inventory management

Inventory Management System

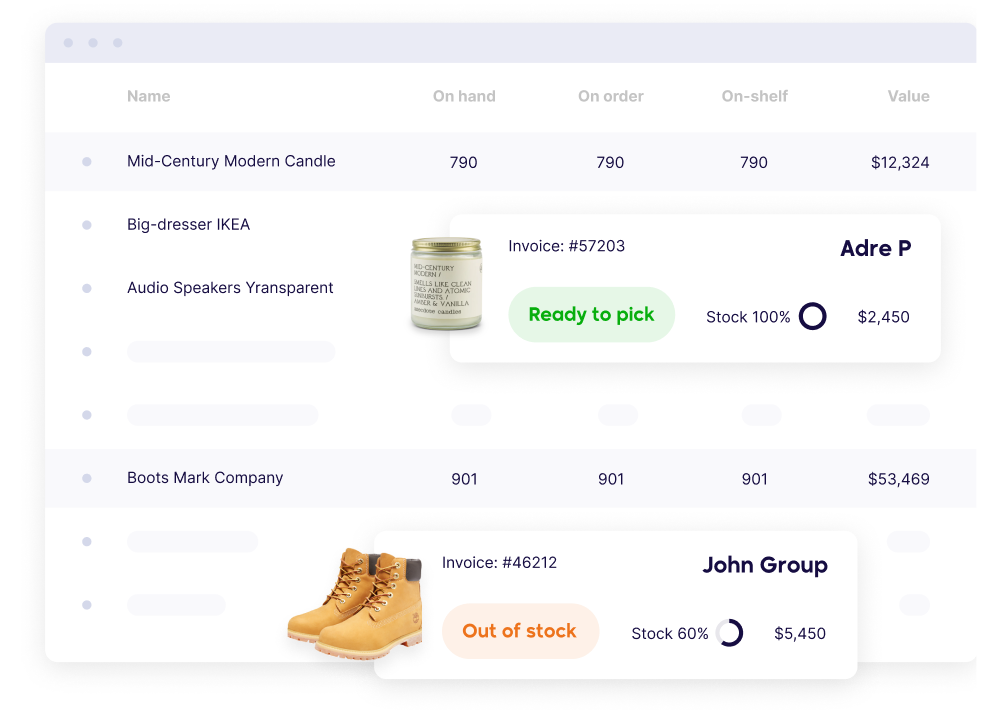

Unlock a comprehensive 360-degree view of your operations with Datapel’s Inventory Management System, the pinnacle of inventory management software designed to elevate your business efficiency. Datapel offers an inventory-centric perspective, complete with item summary, detail, and full drill down capabilities to track inventory data and interactions across multiple locations.

Why Leading Organisations Choose Datapel

Datapel stands as the best inventory management software for precision inventory management. Our system is favoured by industry leaders for its robust inventory tracking and inventory management capabilities, ensuring you’re always ahead in managing your stock levels.

Powerful item search capabilities

Real-time demand indicators by item

Demand planning and order allocation tools

Profile articles with over 30 properties

Detailed stock movement register with audit trail

Strong “back of house” best practice warehouse management principles

Rated 4.4 / 5

Explore the Power of Advanced Inventory Management Systems

Understanding the integral role that inventory management systems play in streamlining operations, Datapel has developed a platform that not only meets the immediate needs of tracking and managing inventory but also provides strategic insights for growth. Our system is designed with the future in mind, accommodating multiple warehouses, complex inventory, and growing business needs seamlessly.

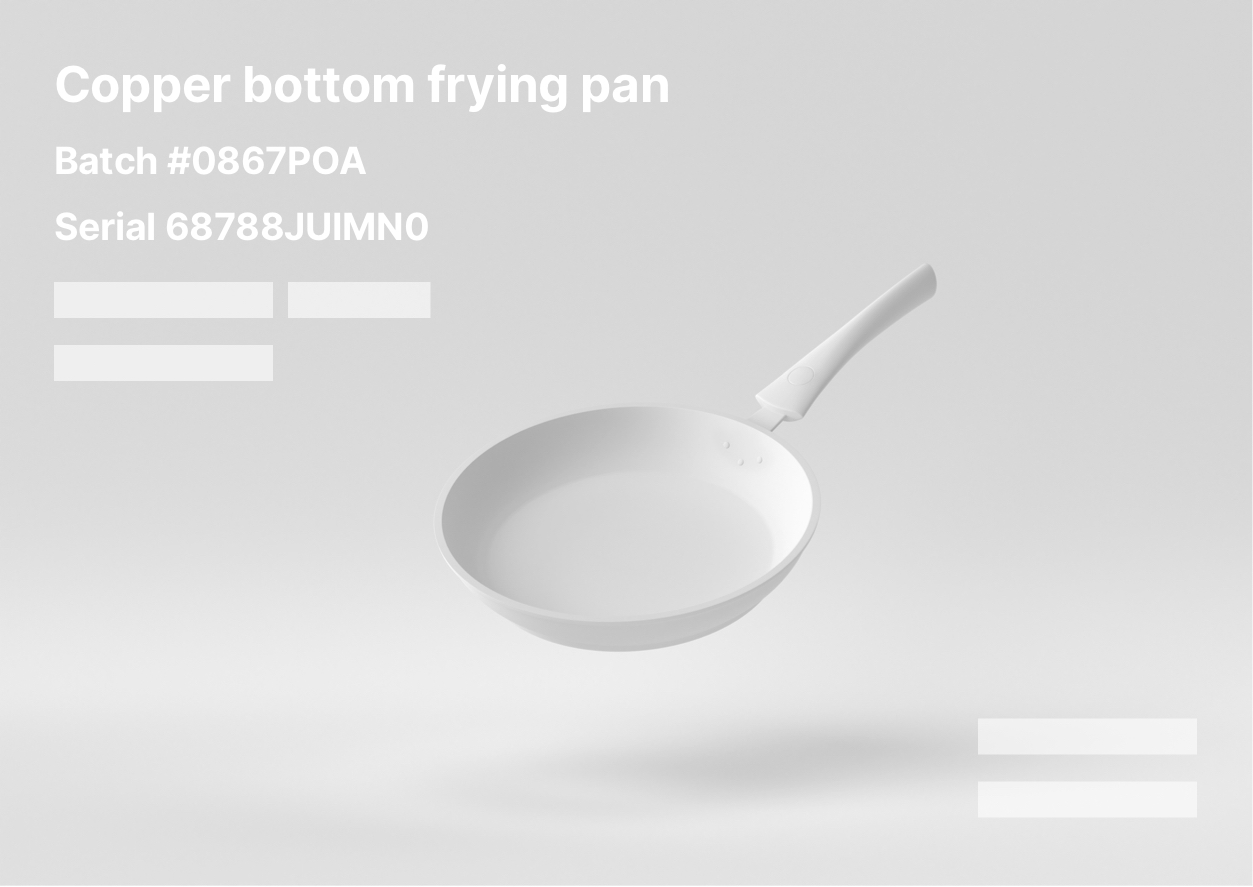

Utilise Precision Item Search

Locate stock effortlessly by item number, name, batch, serial number, bin, custom field, or barcode. Manage inventory across multiple virtual warehouses and bins, maximising efficiency.

Dynamic Demand Forecasting

Stay responsive to changing demand with real-time indicators and inventory management system dashboard analytics for sales channels and inventory levels.

Strategic Planning Tools

Leverage demand planning and order allocation tools for seamless transfers and scheduling, addressing current and future inventory needs.

Article Profiling with Accuracy

Define articles with precision using over 30 properties, enhancing your inventory system with batch tracking, quality control flags, and document attachments.

Gain better visibility through inventory management

Use your detailed stock movement register with audit trail to gain full visibility into article allocation, relocation, or adjustment by worker and location.

High Trust Industries

For sectors demanding utmost reliability like pharma and food and beverage, our inventory management system offers quality control flagging and tailored workflows.

Document Archiving

Support comprehensive document management within the inventory management software, including images, MSDS, EPG, product handling guides, and more.

Rated 4.4 / 5

Increased order accuracy and efficiency

Learn how EHI Australia increased order accuracy and maximised warehouse efficiency. They had outgrown their paper-based system, and needed reliable implementation during rapid business growth.

Take a 360 degree view of your operations and get stock moving faster with effective inventory management.

Coordinate and collaborate with Datapel’s inventory movement and audit trails

Your Datapel Cloud.WMS combines cutting-edge features into one easy, automated system. Built to drive business operations with purchase order software and inventory control workflows to achieve best practice for your industry.

FAQ’s

What is an Inventory Management System?

An Inventory Management System (IMS) is a digital solution designed to track and manage goods throughout an entire supply chain—from purchasing to production to sales. It enables businesses to know in real time what inventory they have, where it is located, and when to reorder to maintain optimal stock levels. By integrating such a system, companies like those using Datapel can lower costs, increase efficiency, and significantly improve inventory control. Datapel’s system offers a comprehensive view of operations, ensuring precise management of stock across multiple locations with ease.

What are the 4 Types of Inventory Management Methods?

-

Just-In-Time (JIT): This method involves keeping inventory levels as low as possible, ordering just enough stock to meet demand. It minimises holding costs but requires precise forecasting and reliable suppliers.

-

ABC Analysis: This method categorises inventory into three categories (A, B, and C) based on importance and value, with A being the most valuable. It helps focus resources on the most impactful items.

-

First-In, First-Out (FIFO): Especially relevant for perishable goods, this method ensures that the oldest stock is sold or used first, reducing the risk of obsolescence.

-

Economic Order Quantity (EOQ): EOQ is a formula used to determine the optimal order quantity that minimises both ordering and holding costs.

What are the 4 Main Steps in Inventory Management?

-

Setting Up Inventory: Identify and categorise inventory items and decide on a management method (e.g., JIT, ABC analysis).

-

Monitoring Inventory Levels: Regularly track stock levels to ensure there’s enough to meet demand without overstocking, utilising tools like Datapel for real-time insights.

-

Forecasting Demand: Use sales data and market trends to predict future inventory needs, adjusting stock levels accordingly.

-

Ordering Inventory: Based on demand forecasts and inventory levels, determine when and how much new stock to order.

What is an Example of an Inventory System?

Datapel’s Inventory Management System is a prime example, offering an all-encompassing solution for tracking and managing inventory with precision. It supports multiple warehousing, barcode integration, quality control flagging, and real-time reporting, making it ideal for businesses seeking to optimise their inventory management.

What are the Three Tools Used to Improve Inventory Management?

-

Barcode Scanning: Streamlines the tracking of stock movements, reduces errors in data entry, and speeds up inventory audits.

-

Inventory Management Software: Like Datapel, these systems provide real-time visibility into stock levels, facilitate order processing, and help with demand forecasting.

-

Demand Forecasting Tools: Utilise historical sales data and analytics to predict future demand, enabling better stock level management.

How Do You Take Inventory?

Taking inventory involves counting, cataloguing, and assessing the value of all inventory items a business holds. Here’s a simplified process:

-

Prepare: Ensure all received stock is accounted for and any recent sales have been processed.

-

Organise Inventory: Group similar items together to streamline the counting process.

-

Count: Physically count each item. Using barcode scanners can expedite this step.

-

Record: Update inventory records with the latest counts, ideally through an inventory management system like Datapel for accuracy and real-time data.

-

Review and Act: Analyse the data to identify trends, discrepancies, or opportunities to adjust stock levels for optimal inventory management.

Advanced Inventory Management System

“Our experience working with Datapel has been absolutely fist class, we have been working with them for over 10 years, they continue to add value each year”