Top Wholesale Trends Shaping Distribution in 2025

Contents

Inventory control is shifting fast. Is your warehouse ready?

Wholesale distribution is a critical part of the ANZ supply chain, connecting local and global manufacturers to retail stores, trade businesses, and eCommerce operators. Across Australia and New Zealand, the wholesale distribution industry supports hundreds of thousands of jobs.

In the year 2024, the gross value added (GVA) by the wholesale trade industry in Australia was around 94.8 billion Australian dollars.

But margins are tightening.

Rising freight costs, labour shortages, volatile demand, and growing customer expectations are putting intense pressure on wholesale operations. Stockouts frustrate loyal customers. Overstock ties up cash. Manual processes cause delays and reduce efficiency.

In 2025, forward-thinking wholesale distributors are adapting using smarter technology, automation, and real-time insights to stay competitive and profitable.

Below, we explore five wholesale distribution trends that are reshaping inventory management in Australia and New Zealand — and how your wholesale distribution businesses can leverage them to stay ahead.

Wholesale Trends Shaping Distribution

1. Smarter Forecasting with AI and Predictive Analytics

Many wholesale distributors are ditching spreadsheets in favour of predictive models powered by artificial intelligence.

Rather than relying on past sales alone, AI-driven forecasting uses data from:

- Seasonal sales trends (e.g. EOFY spikes)

- Promotional campaigns and marketing calendars

- Macroeconomic indicators like inflation or construction activity

- Weather patterns impacting seasonal demand

For example: A Sydney-based electrical distributor might use AI to anticipate a surge in demand for cooling units during an early summer heatwave, instead of reacting to stockouts.

Datapel connects seamlessly with data analytics tools like BI4Cloud and offers a dedicated “Sales Forecasting” module as an optional add-on to help improve planning accuracy. Smarter predictions lead to fewer urgent orders, stronger supplier relationships, and more accurate procurement planning.

Why it matters to ANZ wholesalers:

- Handles long lead times from overseas suppliers

- Aligns stock availability with freight container schedules

- Supports local peaks like Christmas, school terms, or harvest seasons

2. Real-Time Visibility with IoT and Smart Scanning

Accuracy is everything in wholesale distribution. When teams don’t trust stock-on-hand figures, mistakes multiply.

Leading wholesalers are investing in Internet of Things (IoT) devices and smart scanning to deliver real-time inventory visibility. These include:

- RFID tracking for fast-moving or high-value goods

- Barcode scanning at every warehouse touchpoint

- GPS tracking for pallets and deliveries

- Mobile pick/pack verification tools

For example: EHI Australia, a national wholesaler of industrial hardware, transitioned from a paper-based warehouse system to barcode scanning — and saw a 25% improvement in picking efficiency.

“We loved the clarity… I could see exactly what each person was doing, how long it took, and where errors were happening — all through the data.”

– Andrew, Financial Controller & Operations Lead, EHI Australia

Datapel’s barcode-driven WMS helps distributors like EHI gain insights and eliminate guesswork. From goods-in to dispatch, every stock movement is tracked, helping reduce errors and meet evolving customer expectations.

Why it matters for ANZ operations:

- Simplifies compliance for food, medical or industrial goods

- Reduces mislabeled or lost inventory

- Minimises manual stocktake disruptions

Read: EOFY Stocktake Mistakes to Avoid — Lessons from the Warehouse Floor

3. Automated Replenishment That Runs 24/7

Manual reordering is one of the most error-prone and time-consuming parts of wholesale inventory management.

Automated replenishment helps you:

- Set reorder points, preferred suppliers, and quantities

- Auto-generate purchase orders when stock drops

- Avoid overstock and minimise carrying costs

For example: A PPE distributor in Melbourne can set a minimum of 500 units for face masks. When levels drop, a purchase order is triggered, reducing admin and avoiding stockouts.

With Datapel’s Smart Reorder Alerts, distributors can improve efficiency and maintain stock continuity without the admin burden.

Why it matters for the wholesale distribution industry:

- Enables leaner teams to scale operations

- Reduces stockouts and overordering

- Enhances supplier relationship building

4. Warehouse Automation and Task-Based Picking

Warehouse labour is scarce, and costs are rising. To remain competitive, many wholesale distributors are turning to task automation.

You don’t need robots, just smarter workflows:

- Digital picking systems to replace paper slips

- Bin location mapping to reduce walking time

- Task allocation based on order priority or zone

- Custom workflows for different SKUs or UOMs

Datapel supports mobile task assignment, allowing warehouse managers to direct and monitor fulfilment, even across multiple shifts or temp workers.

“Every time you add automation, you’re eliminating another manual step — another person checking, correcting or fixing errors. That’s how we’ve grown the business without adding headcount.” – Edward, Owner, Heebie Jeebies

Why it matters to ANZ wholesale operations:

- Reduces training programs for new hires

- Cuts fulfilment time and error rates

- Supports extended hours and shift work

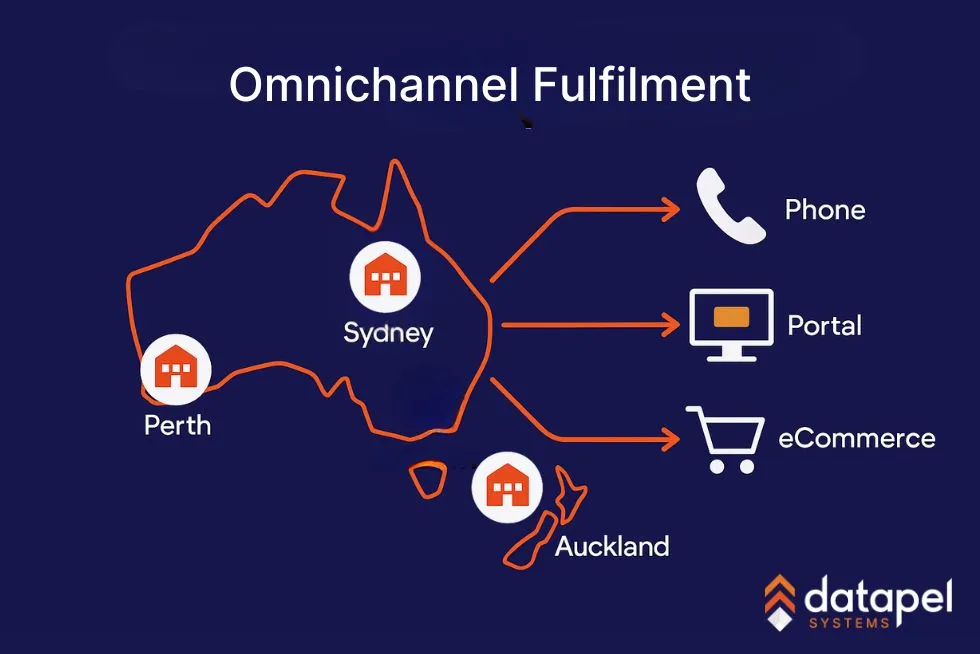

5. Multi-Channel and Multi-Warehouse Coordination

The line between wholesale distribution and eCommerce is blurring. Distributors now need to manage multiple sales channels and warehouse locations while maintaining accuracy.

Datapel enables:

- Real-time inventory sync across warehouses in Sydney, Auckland or Perth

- Location-aware fulfilment based on stock and shipping zones

- Accurate updates for B2B portals and eCommerce platforms like Shopify

Whether you’re servicing retailers, trade clients, or online buyers, Datapel helps prevent double-selling, improves customer satisfaction, and supports long-term success.

Why it matters to wholesale distributors:

- Reduces lost sales due to stock mismatches

- Supports omnichannel business models

- Provides a consistent customer experience

Other Trends Worth Watching

While these five trends are leading change, other market trends are influencing how wholesale distribution evolves:

- Digital transformation is accelerating, driven by new technologies and increased competition.

- Consumer preferences are shifting towards convenience, speed, and transparency.

- Environmental impact is becoming a purchasing factor. Many wholesalers are now focused on reducing waste and tracking their carbon footprint.

- Data analytics are helping companies make informed decisions on stock, pricing, and promotions.

- Value-added services like customer relationship management and tailored packaging are boosting customer loyalty.

Wholesale distribution businesses — including those in the fashion industry and women’s clothing — are adapting their product offerings and pricing to reflect changing consumer behaviour.

As the industry embraces new business models and enters new markets, employee training and customer focus remain crucial components of success.

Wrapping Up: Are You Ready for the Next Wave of Wholesale?

In 2025, staying competitive in wholesale means:

- Tracking inventory in real time

- Automating manual workflows

- Forecasting with data, not gut feel

- Supporting multi-channel fulfilment

- Aligning operations with consumer expectations

With Datapel, you gain the tools and visibility to improve inventory management, increase customer satisfaction, and reduce your environmental impact. At the same time you’ll be protecting profit margins and staying ahead of the latest trends.

Want to see how Datapel can support your wholesale business in 2025?

👉 Request a personalised demo today and explore how we help wholesalers like you deliver faster, reduce costs, and grow smarter with real time visibility.

As a WMS Industry Analyst & Content Lead I write about warehouse management systems from real experience—helping businesses streamline operations, reduce errors, and scale smarter.

Over the past 8 years, I’ve worked closely with warehouse teams, tech developers, and business owners to break down complex supply chain problems into actionable solutions. My goal? Make WMS content useful, not just informative.

When I’m not writing, I’m digging into user feedback, testing new tools, or speaking with industry experts to stay ahead of what matters most to warehouse operators.