ABC Inventory Analysis and How to Use It in Your Business

Contents

If you work in management, then you’re likely aware of the “80/20” rule. Also known as the Pareto Principle, this number states that 80% of your production comes from 20% of your producers. This idea is true for many businesses.

Companies often generate 80% of their business from 20% of their clients. This rule applies to your inventory, too.

You often earn 80% of your business value from 20% of your inventory. But, how can you use this principle to leverage your inventory? That’s where ABC inventory analysis becomes useful.

Keep reading to learn more about the ABC analysis process, and how it can improve your inventory management.

How ABC Analysis Works

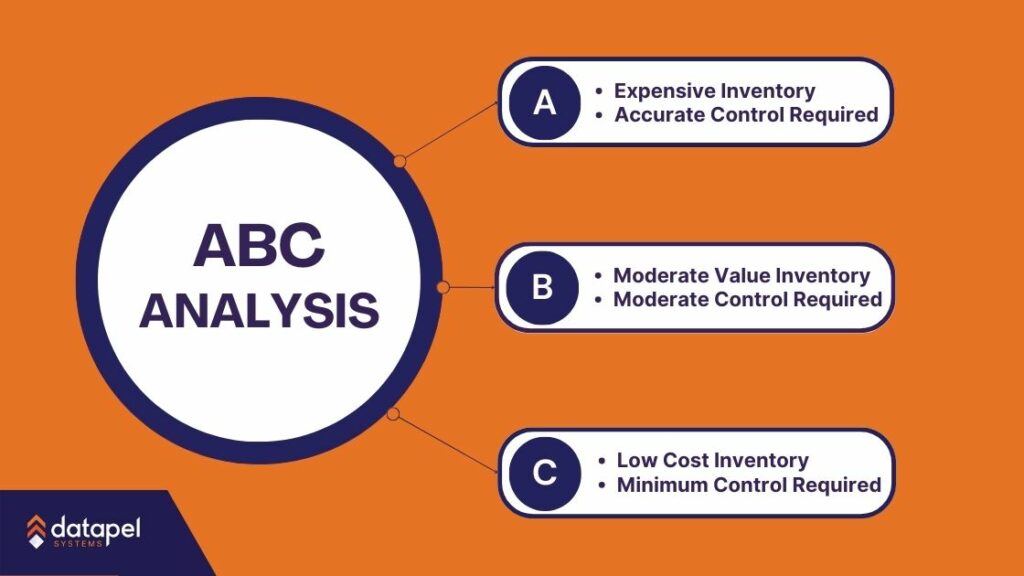

ABC inventory analysis is one of the most well-known inventory management methods. It requires you to divide your products into three categories. Each category (A,B,C) is based on usage value:

A items are your company’s most important products. Products in this category will have high sales volumes, high costs, or both. They’ll account for 10% to 20% of your inventory and 60% to 80 of returns.

B items are important products, but they’re not ranked as highly as A items. This is because they’ll have a lower cost to produce or don’t sell as quickly as A items. They’ll account for 20% to 30% of your inventory and 20% to 30% of your annual consumption value.

C items are the lowest priority items. As per the Pareto Principle, they make up most of your inventory but have the lowest returns. They’ll account for 50% to 70% of your inventory, and 5% to 15% of your annual consumption value.

After items are designated A,B, or C, inventory managers can prioritise tasks accordingly. Say you have to reorder or supervise the supply chain for certain items. Based on the ABC system, dedicate the most resources to A items to minimise loss.

Benefits of ABC Inventory Analysis

The information you’ll gain by using the ABC analysis system will provide dozens of insights into your business operations. Here are just a few areas that will become more efficient after conducting the ABC analysis:

Control Over Inventory

With an ABC analysis, you’ll have more control over your industry. You can increase the supply of high-earning items and lower the amount of less profitable ones as needed. You can also better optimise your storage space based on your ideal amount of inventory.

Stock Forecasting

Understanding what your customers want will help you look to the future. You’ll be able to better estimate how much of a certain product you’ll need in the future, which in turn will give you opportunities to lower production costs and come up with new sales strategies.

Pricing Power

Once you have an idea of which products sell the best, you can adjust your prices to meet demand. Customers will be more than willing to pay more for in-demand products, but less-favoured products may do well with a new discount or marketing strategy.

Better Supplier Deals

Your A items will generate 70% to 80% of your company’s revenue. Since so much of your profits are earned from that amount of your inventory, you’ll have a starting point for negotiations with suppliers.

You can look to reduce costs or get free shipping to keep the cost of your most profitable items low.

Relevant Customer Service

Proving the proper service depends on numerous moving parts, like the inventory’s cost, profit, and amount sold. Determine your most profitable items with the ABC method and offer better service for those items.

Simplified Supply Chain

Have you been on the fence about switching suppliers? It’s hard to tell when you have a lot of inventory. After you conduct an ABC inventory analysis, you’ll have a better idea of your next steps.

Implementing Your ABC Analysis

Ready to use the ABC method? Here are our best tips.

Step 1: Identify Your Problems

First, you need to identify the problem you’re dealing with by analysing your current inventory situation.

What parts of your process are inefficient? Where are you losing the most time?

Also, consider the costs of your inventory. Which products are the most expensive to supply? Are you losing money on any items?

Step 2: Collect Data

To answer your questions, you’ll need to collect some data. Take a look at your inventory over time and notice which items cost the most and the least, as well as which items are selling in the highest volumes.

Other relevant information to note is how quickly products are selling and your inventory turnover ratio.

Step 3: Categorise with ABC

With this data, you can start to analyse your inventory. Sort the items into groups A,B, and C as explained above. Remember that A items are top priority with high consumption, B items have priority but lower consumption, and C items have low priority.

Determine metrics for each category. Calculate the space, cost, and sales. This information will help you decide which products deserve the most attention and resources.

Limitations of ABC Method

For the most part, the ABC method will add value to your inventory system. However, it does have a few limitations to be aware of.

Keep in mind that ABC inventory doesn’t account for items that temporarily change levels. For example, a seasonal product that goes from B to A during the holiday season might be inappropriately categorised.

If you move the item to a new level, you’ll have to reclassify and re-order all of your products. This can be extremely time-consuming. It also makes classifying new items difficult. Since there’s no sales data for new products, the formula will automatically generate a usage value of 0.

However, most companies are willing to work around these drawbacks because the system is otherwise beneficial.

Unlocking Efficiency with ABC Inventory

In summary, the Pareto Principle, known as the “80/20” rule, has a significant impact on management and inventory management.

Utilising ABC inventory analysis, offers numerous advantages, including better inventory control, improved stock forecasting, enhanced pricing strategies, favourable supplier negotiations, and more tailored customer service.

Despite some limitations, the benefits of the ABC method make it a valuable tool for optimising inventory.

If you’re ready to implement ABC analysis, start by identifying inventory issues, collecting relevant data, and categorising items. This approach can lead to increased efficiency and profitability in your business operations.

Your journey to efficient inventory management begins here. Feel free to contact us with any questions or for assistance with ABC analysis implementation. Your success is our priority.