Seasonal and Perishable Inventory Management: Tips for Success

Contents

Managing seasonal and perishable inventory during peak periods can feel like a high-stakes balancing act. Stock too much, and you risk waste. Stock too little, and you miss out on sales.

The good news? With the right strategies, you can keep everything running smoothly—minimising waste, meeting customer demand, and keeping costs under control.

In this guide, we’ll break down practical strategies to help you manage inventory with a limited shelf life, ensuring every item is put to good use.

Why Seasonal and Perishable Inventory Management Matters

Getting perishable inventory right isn’t just about logistics—it directly impacts profitability and customer satisfaction. Here’s why it’s crucial:

- Reduce Waste and Losses – Perishable goods have a shelf life, and poor management leads to unnecessary losses.

- Keep Customers Happy – Stocking fresh, seasonal products when demand is high builds trust and loyalty.

- Improve Profitability – Striking the right balance between supply and demand ensures you avoid stockouts and overstocking.

Let’s explore the key strategies to help you stay in control of seasonal and perishable inventory.

11 Tips for Success

1. Accurate Forecasting and Planning

Predicting demand is the first step towards effective inventory management.

- Use historical sales data and market trends to gauge demand during peak periods.

- Plan ahead by factoring in procurement lead times so you’re not scrambling for stock at the last minute.

- Stay flexible—demand can shift unexpectedly, so be ready to adjust your orders if needed.

When you understand demand patterns, you can stock smarter, reduce excess inventory, and keep operations running smoothly.

2.Implementing Just-in-Time (JIT) Inventory

Just-in-Time (JIT) inventory management is about efficiency—bringing stock in only when needed.

- Reduce excess stock by working with suppliers to align deliveries with real-time demand.

- Lower storage costs and minimise spoilage by keeping only what is necessary.

JIT works particularly well for perishable goods, ensuring products are fresh while avoiding unnecessary waste.

3. Batch Control for Better Tracking

Batch control helps you track stock effectively and manage perishables with confidence.

- Break stock into smaller batches to reduce spoilage and improve oversight.

- Use batch tracking systems to monitor expiry dates and ensure older stock is used first.

By managing inventory in batches, you can quickly identify and act on any quality issues before they escalate.

4. First-In, First-Out (FIFO) Rotation Strategy

A simple yet powerful approach to inventory management, FIFO ensures the oldest stock is used or sold first.

- Keep older products easily accessible to prevent them from being overlooked.

- Regularly inspect inventory to ensure FIFO is being followed.

Following FIFO helps reduce expired stock and keeps customers happy with fresh products.

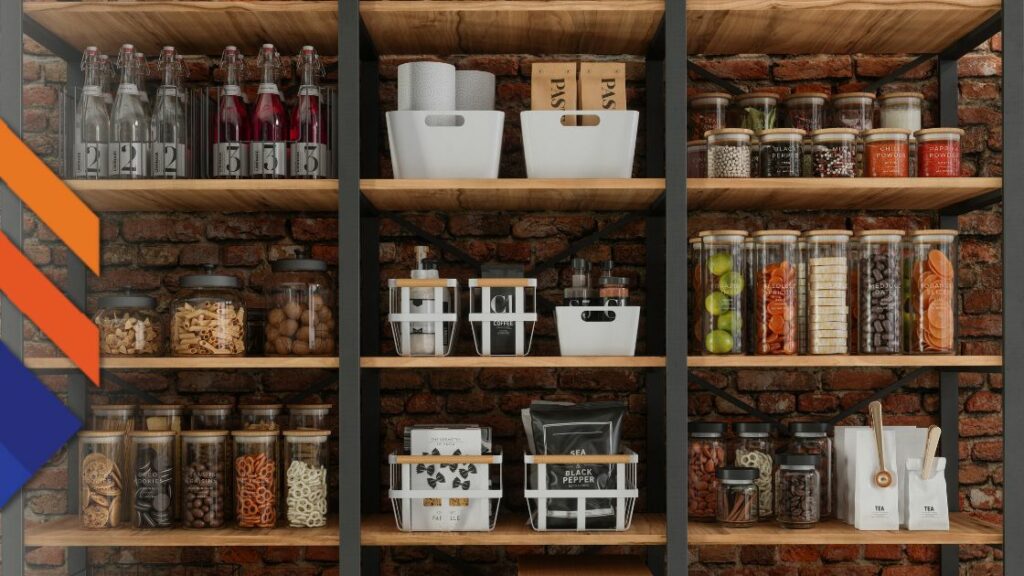

5. Smart Shelving and Storage

How you store your inventory makes a big difference in efficiency.

- Label shelves clearly so staff can find and pick stock quickly.

- Organise by expiry date to ensure older stock moves first.

- Use climate-controlled storage for highly perishable items like dairy and fresh produce.

Good organisation saves time, minimises errors, and ensures stock is used effectively.

6. Using Inventory Tracking Software

Automating inventory management makes operations more efficient.

- Get real-time stock visibility to track expiration dates and monitor stock levels.

- Use barcode scanning or RFID to improve accuracy and streamline operations.

With the right inventory management software, you can reduce manual errors and stay ahead of stock fluctuations.

7. Using Promotions to Clear Stock

If a product is approaching its sell-by date, don’t let it go to waste—discount it.

- Run time-sensitive promotions to encourage quick sales.

- Label items clearly so customers know they’re getting a good deal.

Offering discounts on expiring stock helps reduce waste and increase sales.

8. Working Closely with Suppliers

Your suppliers can be valuable partners in managing perishable inventory.

- Communicate regularly to adjust orders based on real-time demand.

- Negotiate flexible deliveries to avoid holding excess stock.

A strong supplier relationship helps keep inventory lean and responsive to changes.

9. Reducing Waste

Minimising waste is not just about saving money—it is also good for the environment.

- Monitor waste patterns and identify where stock losses occur.

- Donate surplus food to charities where possible, rather than letting it go to waste.

- Adjust ordering processes based on previous waste insights to prevent overstocking.

By making small changes, you can significantly cut down on waste and improve sustainability.

10. Employee Training for Inventory Success

Your team plays a crucial role in inventory management. Well-trained employees mean fewer mistakes and better stock control.

- Teach FIFO best practices so everyone understands how to manage stock effectively.

- Ensure proper handling of perishables to maintain product quality.

- Train staff on inventory software so they can track and manage stock accurately.

Regular training keeps your team sharp and inventory running smoothly.

11. Leveraging Data Analytics

Data provides valuable insights that can refine inventory strategies.

- Track customer buying patterns to adjust stock levels accordingly.

- Analyse trends and inventory turnover to identify what sells best and when.

- Use insights to fine-tune purchasing decisions.

A data-driven approach helps businesses stay ahead of demand fluctuations and avoid costly stock mismanagement.

Conclusion

Managing seasonal and perishable inventory successfully requires a mix of planning, technology, and strategic decision-making.

By applying these strategies, you can:

- Keep stock fresh and relevant.

- Reduce waste and unnecessary costs.

- Improve efficiency and customer satisfaction.

With the right approach, your business can stay ahead—whether it is peak season or not.

Frequently Asked Questions (FAQs)

What is seasonality in inventory management?

Seasonality in inventory management refers to fluctuations in demand for certain products at specific times of the year. This can be due to holidays, weather changes, or industry trends. Businesses must plan ahead to ensure they have enough stock to meet demand without overstocking and increasing holding costs.

What is perishable inventory?

Perishable inventory includes products that have a limited shelf life and can spoil, degrade, or become obsolete over time. This includes food, beverages, pharmaceuticals, and certain beauty or chemical products. Managing perishable inventory effectively involves using rotation strategies like FIFO and batch tracking to minimise waste.

What is an example of seasonal inventory?

Seasonal inventory includes products that see a spike in demand during specific periods. Examples include Christmas decorations in December, winter clothing in colder months, or sunscreen and outdoor furniture during summer. These products require careful inventory planning to avoid overstocking or stockouts.

How do you identify seasonal products?

Identifying seasonal products involves analysing historical sales data to spot trends in demand fluctuations. Other indicators include industry patterns, customer purchasing behaviour, and external factors such as holidays or weather changes. Businesses can also track supplier lead times and competitor stock levels to anticipate seasonal demand more effectively.

In my role, I oversee the development of insightful blogs that delve into the intricacies of warehouse management. Each piece reflects my dedication to empowering businesses through informative content. Through my team’s extensive experience in the industry, we aim to bring clarity to the complexities of WMS, helping businesses make informed decisions.

Join me on a journey through the ever-evolving landscape of warehouse technology as we explore the latest trends, industry insights, and practical tips to streamline your operations. Feel free to connect, and let’s embark on a collaborative exploration of how WMS can redefine your business efficiency.

Cheers to innovation, efficiency, and the exciting world of warehouse management!