Mastering Minimum Order Quantity (MOQ) for Smarter Inventory Management

Contents

Ever found yourself stuck between ordering too much stock and not having enough? That’s where Minimum Order Quantity (MOQ) comes in. MOQ is a key factor in warehouse management that directly impacts your costs, cash flow, and efficiency. But getting it right can be tricky. Order too much, and you’re left with excess inventory eating up space and money. Order too little, and you risk stockouts and frustrated customers.

This blog will break down everything you need to know about MOQ in simple terms. You’ll learn why it matters, how to determine the right MOQ for your business, and how to balance cost-effectiveness with flexibility.

Why This Topic Matters:

- Saves Money: Understanding MOQ helps reduce inventory waste and storage costs.

- Improves Cash Flow: Ordering the right amount ensures you don’t tie up too much money in stock.

- Boosts Efficiency: With the right MOQ, you can optimise your supply chain and avoid unnecessary disruptions.

What is Minimum Order Quantity(MOQ)?

MOQ refers to the smallest amount of a product a supplier is willing to sell in a single order. This number is set based on production costs, supply chain considerations, and business profitability.

For example, a clothing manufacturer might set an MOQ of 500 units per style to ensure economies of scale, while an electronics supplier may require a minimum of 100 units due to the costs involved in production and shipping.

How to Calculate MOQ

Determining the right MOQ requires understanding production costs, demand, and storage capacity. Here’s a simple formula:

MOQ = Total Cost of Order / Unit Cost of Product

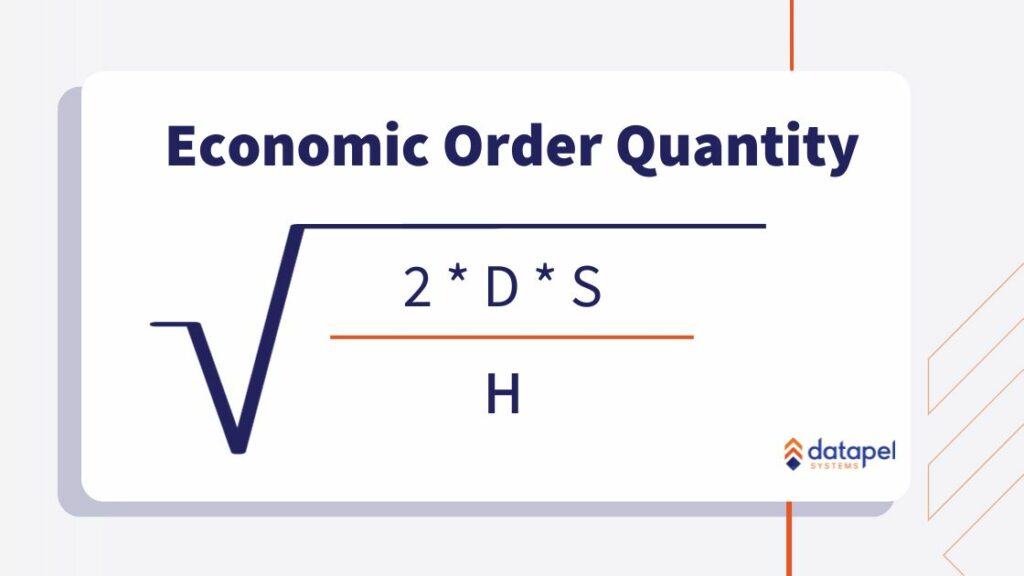

For a more strategic approach, businesses can use the Economic Order Quantity (EOQ) formula:

EOQ = √((2DS)/H)

Where:

- D = Annual demand (units per year)

- S = Ordering cost per order

- H = Holding cost per unit per year

This formula helps businesses minimise total inventory costs while ensuring they order optimal quantities.

Understanding Economic Order Quantity (EOQ)

While MOQ sets the minimum purchase requirement from a supplier, EOQ helps businesses determine the most cost-effective order quantity. The goal of EOQ is to balance ordering costs and holding costs, ensuring businesses don’t over-order or run into frequent stock replenishment issues.

By using EOQ calculations, businesses can:

- Optimise their ordering cycles to avoid unnecessary storage costs.

- Reduce order frequency, lowering administrative and handling costs.

- Maintain a steady stock level, ensuring product availability without excessive overstocking.

EOQ is particularly useful for businesses dealing with fluctuating demand, helping them make data-driven purchasing decisions that align with their cash flow and storage capacity.

High MOQ vs Low MOQ: What’s the Difference?

High MOQ

A high MOQ means purchasing larger quantities in a single order. This can be beneficial for suppliers as it reduces per-unit costs, but it may be challenging for businesses with limited storage or cash flow.

Example: A wholesale food distributor may require retailers to buy a minimum of 1,000 units per product to keep production costs low.

Low MOQ

A low MOQ allows businesses to purchase smaller quantities, reducing inventory risks but often at a higher per-unit price.

Example: An online fashion boutique may prefer suppliers with low MOQ (e.g., 50 items per design) to avoid overstocking and maintain flexibility in product offerings.

How MOQ Impacts Different Industries

MOQ affects industries differently based on supply chain structure, demand, and operational costs. Here’s how it applies to key sectors:

Wholesale & Distribution

Wholesalers often face high MOQs due to bulk purchasing agreements with manufacturers. To stay competitive, they need to negotiate better terms with suppliers while managing stock efficiently.

Manufacturing

Manufacturers set MOQs based on production efficiency. A higher MOQ helps reduce production costs, but too high an MOQ can discourage potential buyers, particularly small businesses.

Retail & E-Commerce

Retailers must balance MOQ with sales forecasts. Large retail chains can absorb higher MOQs due to vast distribution networks, while smaller eCommerce stores may struggle with storage limitations.

Food & Beverage

Perishable goods require careful MOQ calculations. Buying in bulk may reduce costs, but businesses must consider shelf life to avoid waste.

How to Make MOQ Work for Your Business

1. Negotiate with Suppliers

If a supplier’s MOQ is too high, negotiate by offering long-term commitments, flexible payment terms, or increased order frequency.

2. Use EOQ for Smarter Ordering

Calculate EOQ to find the most cost-effective order quantity, ensuring minimal storage costs while avoiding stockouts.

3. Consider Alternative Supply Chain Strategies

Dropshipping or just-in-time (JIT) inventory management can help businesses with cash flow constraints by reducing inventory holding costs.

4. Test Before Committing to Large Orders

Order small batches initially to evaluate demand before committing to large MOQ agreements.

5. Diversify Suppliers

Working with multiple suppliers can provide flexibility, reducing dependency on one vendor’s MOQ requirements.

In Conclusion

MOQ plays a crucial role in managing inventory, controlling costs, and ensuring business profitability. While high MOQs can lower per-unit costs, they require substantial investment and storage. Low MOQs offer flexibility but can be more expensive per unit.

By using strategic calculations like EOQ, negotiating with suppliers, and choosing the right inventory model, businesses can optimise MOQ to suit their needs. Ultimately, it’s about finding the right balance between cost-effectiveness and flexibility that works with your inventory system.

FAQ’s

1. What is the difference between MOQ and EOQ?

MOQ is the minimum quantity a supplier requires you to purchase, while EOQ is the optimal order size that minimises costs.

2. How do I ask a supplier to lower their MOQ?

You can negotiate by offering long-term contracts, committing to regular orders, or asking for tiered pricing.

3. What happens if I can’t meet a supplier’s MOQ?

You can look for another supplier, try negotiating, or consider joining a buying group to meet the minimum requirement.

4. Can MOQ impact my profit margins?

Yes, a high MOQ can lower per-unit costs but ties up cash in stock, while a low MOQ increases flexibility but might lead to higher per-unit prices.

5. What industries benefit most from MOQ strategies?

Any business dealing with inventory, especially wholesalers, retailers, manufacturers, and eCommerce stores, can benefit from an effective MOQ strategy.

In my role, I oversee the development of insightful blogs that delve into the intricacies of warehouse management. Each piece reflects my dedication to empowering businesses through informative content. Through my team’s extensive experience in the industry, we aim to bring clarity to the complexities of WMS, helping businesses make informed decisions.

Join me on a journey through the ever-evolving landscape of warehouse technology as we explore the latest trends, industry insights, and practical tips to streamline your operations. Feel free to connect, and let’s embark on a collaborative exploration of how WMS can redefine your business efficiency.

Cheers to innovation, efficiency, and the exciting world of warehouse management!