Inventory Days Formula and Its Value in Effective Inventory Management

Contents

At Datapel, we understand the significance of efficient inventory management for businesses of all sizes. One crucial aspect of inventory management is calculating inventory days, which provides valuable insights into the health and performance of your inventory.

In this article, we will delve into the inventory days formula and explain why it is a useful metric for optimising inventory control. Through our expertise and comprehensive analysis, we aim to provide you with the most insightful and valuable information on this topic.

What is Inventory Days?

Inventory days, also known as days inventory outstanding (DIO), is a metric used to determine the average number of days it takes for a company to convert its inventory into sales. It provides a clear perspective on the efficiency of inventory turnover and helps identify areas where improvements can be made. By calculating the inventory days, businesses gain a deeper understanding of their inventory management practices and can make informed decisions to optimise their operations.

The Inventory Days Formula

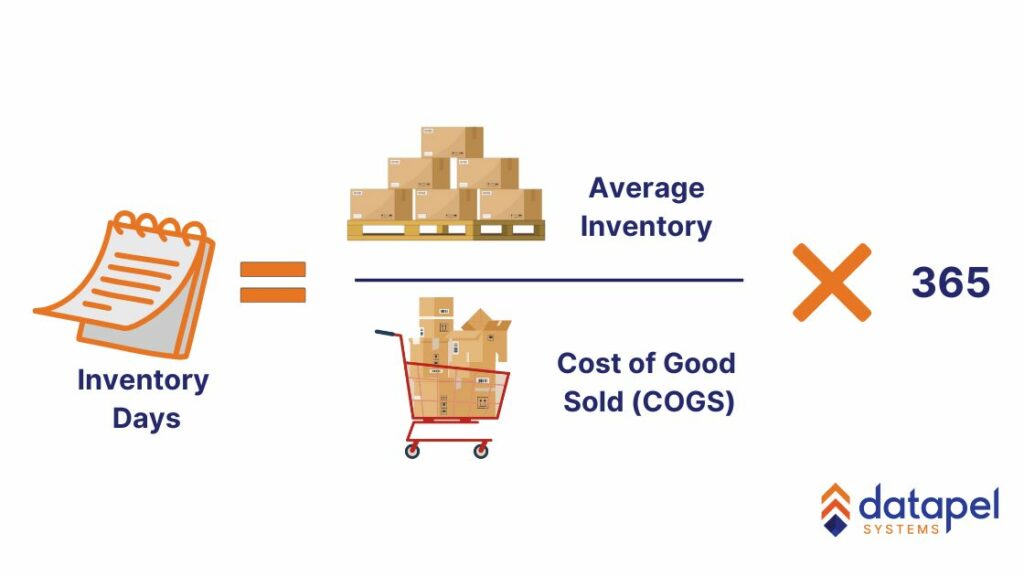

To calculate the inventory days, you need two key pieces of information: the average inventory value and the cost of goods sold (COGS). The formula is as follows:

Inventory Days = (Average Inventory Value / COGS) × 365

Let’s break down the components of this formula to better understand their significance:

- Average Inventory Value: This refers to the average value of inventory held during a specific period. It can be calculated by adding the opening inventory value and closing inventory value, then dividing the sum by two.

- Cost of Goods Sold (COGS): COGS represents the total cost incurred by a business to produce or acquire the goods sold during a given period. It includes the cost of raw materials, direct labour, and any other direct costs associated with the production or procurement of goods.

By combining these two variables, the inventory days formula provides a tangible metric that helps businesses assess the efficiency of their inventory management processes.

The Importance of Inventory Days in Inventory Management

Efficient inventory management is essential for maintaining healthy cash flow, reducing carrying costs, and meeting customer demand. Inventory days serve as a key performance indicator (KPI) that offers several valuable benefits:

1. Identifying Inventory Holding Costs

By calculating inventory days, businesses can identify the costs associated with holding excess inventory. Carrying costs, such as storage, insurance, and depreciation, can significantly impact a company’s profitability.

A high inventory days figure indicates that inventory is sitting idle for an extended period, tying up capital that could be invested elsewhere. Through regular monitoring and analysis of inventory days, businesses can identify opportunities to reduce holding costs and increase overall efficiency.

2. Optimising Stock Levels

The inventory days formula allows businesses to strike a balance between stocking enough inventory to meet customer demand and avoiding excess stock that could lead to increased holding costs.

By tracking inventory days over time, businesses can identify trends and patterns, enabling them to make data-driven decisions regarding optimal stock levels. This helps prevent stockouts and backorders, leading to improved customer satisfaction and increased revenue.

3. Streamlining Supply Chain Management

Inventory days also provide valuable insights into supply chain efficiency. By analysing the time it takes for inventory to convert into sales, businesses can identify bottlenecks in their supply chain processes.

This information allows for targeted improvements, such as reducing lead times, optimising order quantities, or enhancing communication with suppliers. By streamlining the supply chain, businesses can improve overall productivity, reduce costs, and enhance customer service.

Utilising Inventory Days to Enhance Inventory Management

Now that we understand the significance of inventory days, let’s explore some actionable strategies for leveraging this metric to optimise inventory management:

1. Regular Monitoring and Analysis

Consistently tracking and analysing inventory days is essential for identifying trends, patterns, and areas for improvement. Implement a robust inventory management system that provides real-time data on inventory levels, sales, and COGS.

Regularly review and compare inventory days across different product categories or suppliers to identify outliers and take necessary actions.

2. Forecasting and Demand Planning

Accurate demand forecasting is vital for preventing stockouts and minimising excess inventory. Utilise historical sales data, market trends, and customer insights to develop reliable demand forecasts.

By aligning your inventory levels with expected demand, you can minimise the risk of holding excessive stock and optimise inventory turnover.

3. Implementing Just-in-Time (JIT) Inventory Management

Just-in-Time (JIT) inventory management is a strategy aimed at reducing waste and improving efficiency by receiving inventory only when needed. By closely coordinating with suppliers and utilising accurate demand forecasts, you can minimise days of inventory while ensuring that you have sufficient stock to meet customer demand promptly.

4. Embracing Automation and Technology

Leveraging inventory management software and automation tools can significantly streamline and enhance your inventory control processes.

These technologies provide real-time insights, automate order management, and facilitate accurate inventory tracking. By embracing the right tools, you can improve accuracy, reduce manual errors, and make data-driven decisions to optimise inventory management.

Conclusion

Effective inventory management plays a critical role in the success of any business. Calculating inventory days by using the formula discussed above, provides valuable insights into inventory turnover, holding costs, and supply chain efficiency.

By regularly monitoring this metric and implementing strategies to optimise inventory management, businesses can enhance profitability, streamline operations, and meet customer demand effectively.

At Datapel, we are committed to helping you achieve optimal inventory management practices and drive your business forward. Book a personalised demo and start your free trial today.

In my role, I oversee the development of insightful blogs that delve into the intricacies of warehouse management. Each piece reflects my dedication to empowering businesses through informative content. Through my team’s extensive experience in the industry, we aim to bring clarity to the complexities of WMS, helping businesses make informed decisions.

Join me on a journey through the ever-evolving landscape of warehouse technology as we explore the latest trends, industry insights, and practical tips to streamline your operations. Feel free to connect, and let’s embark on a collaborative exploration of how WMS can redefine your business efficiency.

Cheers to innovation, efficiency, and the exciting world of warehouse management!