Ecommerce Warehousing: Types, Fundamentals, and Best Practices

Contents

Although eCommerce dates back to 1969, it’s come a long way since the CompuServe launch. eCommerce sales now account for 14.1% of total sales in the US—and at the global scale, that number rises to 19.7%.

Advancements in technology have made it easier both for consumers and business owners. Consumers can order just about anything from their laptops and have it at their doorstep within a few days (or hours).

However, aspiring entrepreneurs can also start eCommerce businesses from their laptops and have them running within the same time frame. With over 12 million eCommerce stores globally, the places that store inventory are the backbone of digital retail.

And that’s where eCommerce warehousing comes into play.

What is eCommerce Warehousing, Exactly?

eCommerce warehousing refers to the essential process of stocking products, organising them, and getting them ready for shipping.

It includes receiving and inspecting incoming products from vendors, creating accurate records of inventory levels in a database, labelling/tagging stock items, organising them into sections or bins, wrapping or boxing up orders for shipment, and ensuring that all outbound shipments are correctly identified and tracked.

It’s a critical component of any eCommerce business that needs to be managed efficiently if you want your business to thrive.

Types of eCommerce Warehouses

Technically, anything that stores eCommerce inventory functions as a “warehouse.” But that doesn’t mean that all warehouses are the same. Here are a few common types of eCommerce warehouses:

1. Private Warehouses

If a business owns its facility, it’s a private warehouse. Private warehouses are not shared with any other businesses and offer the business owner the most control. They also tend to be more costly, as they require additional overhead investments in staffing and equipment.

Examples of private warehouses include Amazon fulfilment centres, supermarkets, and other large retail stores. An eCommerce company would only invest in a private warehouse if it needs complete control over its inventory and supply chain processes (and has the capital to do so).

2. Public Warehouses

Public warehouses are owned by governments, corporations, or other entities that lease out space to companies for a low cost. They’re generally cheaper than private warehouses, but they aren’t the most technologically advanced.

Businesses that use public warehouses usually don’t need a lot of control over their inventory and supply chain processes. They also don’t have much inventory to begin with (e.g., a local clothing company).

3. Cooperative Warehouses

A cooperative warehouse is a shared facility owned and operated by multiple businesses. It’s similar to a public warehouse, but the owners have more control over their inventory management than if an outside provider handled it.

The main benefit of using a cooperative warehouse is that it allows businesses to pool resources and share costs, making the overall warehousing and logistics process more efficient. It’s also ideal for businesses that require specific storage requirements, as they can customise the facility to meet their needs.

In general, cooperative warehouses provide an economical solution for growing companies that can’t yet invest in a private warehouse.

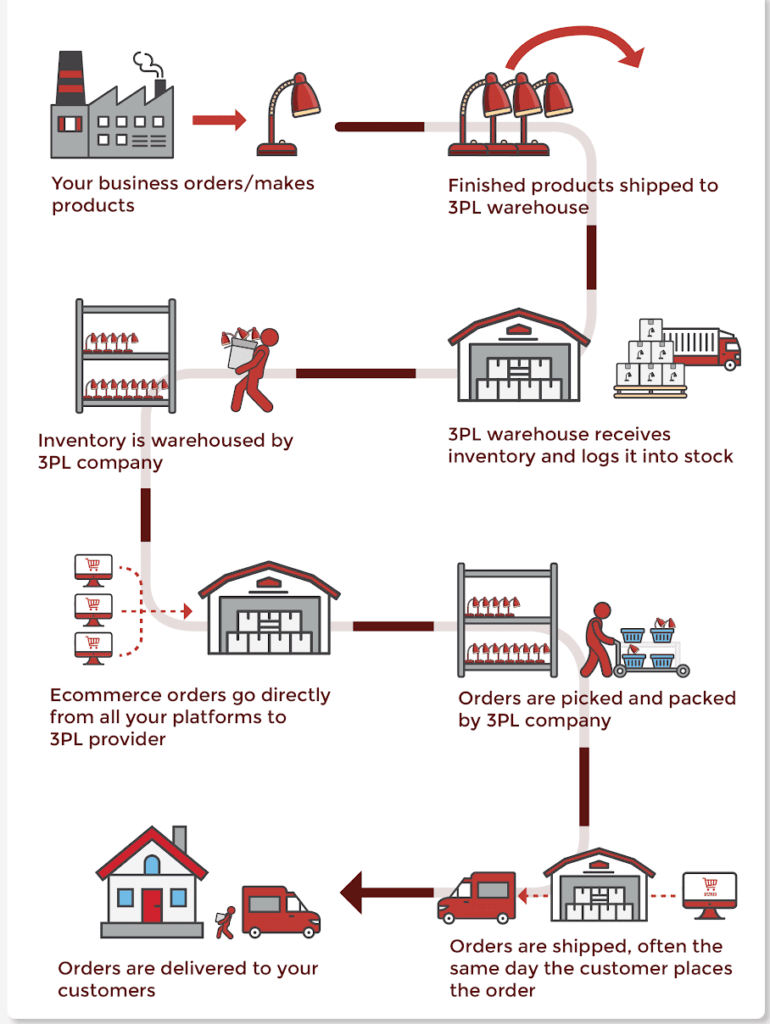

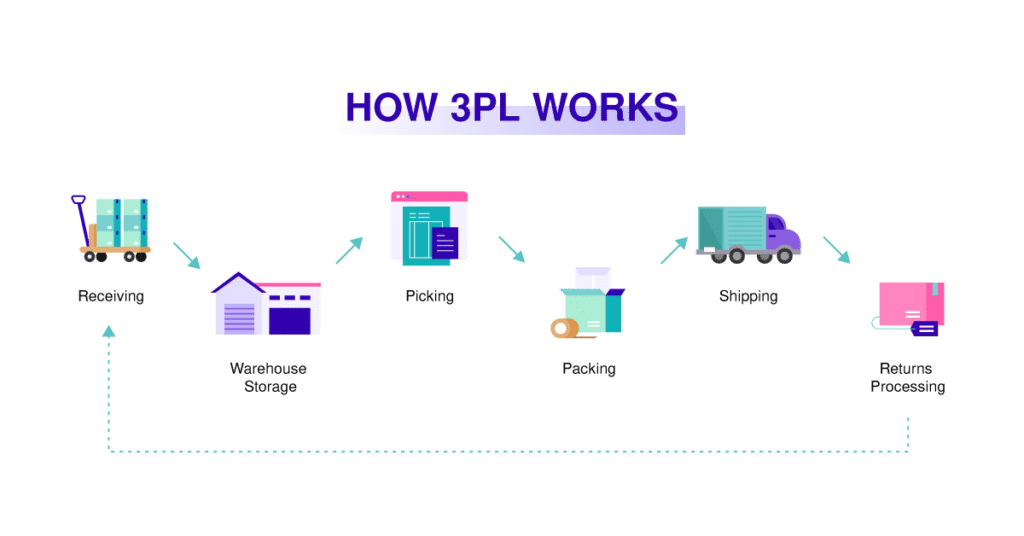

4. Third-Party Logistics (3PL)

Third-party logistics (3PL) centres, also known as fulfilment centres, are distribution centres owned and operated by a third-party company. They tend to be larger than private warehouses and offer better scalability for businesses that frequently experience peaks and valleys in their order volume.

By definition, 3PLs only handle order fulfilment, but most of them have such a large inventory capacity that businesses also use them for warehousing. This is known as vendor-managed inventory (VMI), a supply chain model that improves inventory management and continuity of product delivery.

Most businesses use 3PLs because they free up their resources, allowing them to focus on other areas of their operations.

5. Dropshipping Warehouses

Dropshipping is an eCommerce business model in which an online retailer doesn’t store any inventory at all—instead, it outsources its inventory management to suppliers or manufacturers. When a customer orders, the retailer forwards the order details to the supplier, who then fulfils the shipment directly to the customer.

The difference between dropshipping and using a 3PL is that with dropshipping, the product manufacturer or distributor is responsible for the warehousing and shipping process. Using a 3PL, the fulfilment centre is a separate entity that ships the orders to customers.

Many new market entrants use this strategy to test their product ideas, as it requires minimal upfront capital and effort. However, it can also be quite unreliable, as the retailer has no control over inventory levels or order delivery times (which are often slow).

6. Cross-Docking Warehouses

Cross-docking warehouses are specialised warehouses with limited storage space that facilitate the quick transfer of goods from one truck to another. They’re used when products need to be moved quickly, such as in the case of perishable foods and medications.

In cross-docking warehouses, incoming trucks are unloaded directly onto outbound trucks or the end customer without intermediate storage.

Using a consolidated warehouse like this reduces inventory costs since there’s no need to store goods in-house, and also decreases delivery time as products are ready to ship almost immediately after arriving.

7. Smart Warehouses

Smart warehouses use robotics, automated storage systems, and other advanced technologies to reduce manual labour. As eCommerce orders become more complex and require faster delivery times, smart warehouses are becoming increasingly popular.

They’re particularly useful for businesses with large order volumes, as they allow them to quickly fulfil orders with minimal labour costs. Warehouse automation offers better inventory control, as robots can quickly identify and pick items without manual intervention.

At this moment, most large companies like Amazon, Coca-Cola, Walmart, and PepsiCo can afford to invest in a smart warehouse. But as technology becomes more accessible, most private, public, and dropshipping warehouses will eventually benefit from warehouse automation.

8. Garages

Many eCommerce business owners use their own garages as eCommerce warehouses. Reasons for this include:

- Warehousing is too expensive to justify the costs.

- The business is too small to require a warehouse.

- The business doesn’t have an extensive inventory.

- The owner creates limited edition product runs and doesn’t have a consistent inventory.

Many small business owners don’t know that they could outsource their warehousing for a relatively low cost, depending on the size and complexity of their operations.

Using a garage for eCommerce warehousing is usually only effective if the business has limited inventory, or if it doesn’t need to ship items quickly. In any other case, outsourcing to an experienced 3PL is likely a better choice.

5 Reasons to Warehouse Your Products

Small or large, warehousing positively impacts eCommerce businesses. Here are five reasons why you should consider warehousing your products:

1. Faster, more reliable delivery.

Customers expect faster delivery times and reliable service thanks to the Amazon effect. Providing a faster and more reliable delivery can be a major competitive advantage for your business and customer experience.

For this reason, it is also best to distribute your product across multiple warehouse locations across whichever country you market, sell, and ship to—especially if it’s a larger country (e.g., the USA).

2. Better control over inventory.

Selling a few items without a warehouse is manageable. But when you start selling many different items and managing multiple orders, it’s hard to keep track of inventory without a warehouse.

A good warehouse system will reduce the risk of stockouts or overstocks and help you better manage incoming shipments.

At scale, inventory management is even more essential—incorrect shipments, missed delivery deadlines, and stockouts can quickly damage customer relations and lead to huge losses in sales.

3. Lower costs in the long run.

Using a 3PL instead of your own eCommerce warehouse might seem more expensive when you get it set up, but as your eCommerce store grows, you’ll save money.

For example, hiring an experienced 3PL to manage your warehousing needs (including order fulfilment and shipping) can be more cost-effective than hiring in-house staff to do the same job.

In addition, 3PLs often offer discounts when eCommerce retailers commit to long-term contracts. These lower costs can make it easier for your business to stay profitable even during times of high demand or rapid growth.

Plus, if you ever decide to scale, you’ll need to graduate to some form of eCommerce warehousing anyway. The sooner you can cultivate positive vendor relationships, the better.

4. Single-item picking.

Decades ago, warehouses were used almost exclusively for storing items until customers ordered them. Today, warehouses are becoming automated and sophisticated enough to handle single-item picking. This means that each item is picked from the shelf and not bundled together with other items.

Single-item picking allows for orders to be fulfilled faster, but it also requires more complex software systems that can track inventory in real time and quickly adjust stock levels—something that warehouses now offer.

5. Easier returns management.

Returns are inevitable in eCommerce—around 20% of eCommerce orders end up back where they started. Some buyers return over half of the items they purchase.

It’s essential to have a returns management system that can easily track orders, process returns, and restock items.

Some 3PLs offer specialised software systems that make it easy for customers to initiate return requests and quickly get their money back. These same companies also offer automated inventory tracking systems that alert you when new stock is required.

What is eCommerce Warehouse Management?

eCommerce warehouse management is the collection of systems and processes that ensure accurate inventory tracking, order picking and packing, shipping, and other warehouse activities related to eCommerce operations.

Warehouse operations involve numerous activities:

- Managing and maintaining an accurate inventory.

- Organising the goods stored in a warehouse.

- Picking and packing orders accurately and quickly.

- Handling returns and refunds.

- Maintaining warehouse equipment.

- Ensuring all orders are shipped on time.

- Training and managing warehouse staff.

- Forecasting future volume, labour demand, and equipment needs.

- Maintaining a safe and secure working environment.

At its core, eCommerce warehousing is all about creating an efficient system for storing and keeping track of products so eCommerce sellers can quickly fulfil customer orders. It also involves optimising the workflow within a warehouse to reduce errors and speed up the order fulfilment process.

What is an eCommerce Warehouse Management System (WMS)?

If eCommerce warehousing sounds difficult, it’s because it is.

As we mentioned, several elements must come together across the entire eCommerce supply chain to create an efficient system. And when a customer orders something from an eCommerce store, it’s not just a matter of pulling the item off the shelf and shipping it out.

That’s why every eCommerce retailer needs an eCommerce warehouse management system (WMS) to help manage their inventory and fulfilment processes. A WMS is a software solution designed to manage eCommerce warehousing activities.

These systems come in both cloud-hosted and on-premise varieties—although these days, most companies prefer a cloud option because of its scalability and accessibility.

Features of warehouse management systems include:

- Real-time inventory tracking. A cloud-based system can track inventory levels in real time, so you always know what’s in stock and can adjust accordingly, even across multiple locations and bins.

- Order picking and packing automation. A WMS can automate the process of order picking and packing, reducing errors and speeding up the entire process.

- Shipping and order fulfilment. Using a barcode system and cloud computing, a WMS can generate shipping labels, track packages, and give customers more precise updates on their orders.

- Returns management. A WMS helps eCommerce sellers manage returns and refunds, so they don’t have to worry about losing time or money if a customer decides to return something.

- Purchase and freight carrying. Built into the system, you can track purchase orders and freight carriers to keep up with incoming shipments.

- Documentation and auditing. A WMS can generate documents related to inventory and orders, as well as audit records for compliance.

- Real-time inventory visibility and powerful BI reporting tools. WMS systems also generate reports to help you track and analyse metrics like inventory levels, sales trends, supplier performance, and more.

- Integration with other business systems. Beyond inventory and order management, an eCommerce WMS can be integrated with other systems like ERP and CRM.

Another benefit of using a WMS is its simplicity. Our warehouse management system lets you manage all of these tasks from a single dashboard, so you can quickly see which orders have been fulfilled and which are still in progress.

Fundamentals of eCommerce Warehouse Management

Poor eCommerce warehousing processes can result in lost orders, late deliveries, and unhappy customers. Several key principles should be considered when setting up eCommerce warehousing regardless of how you plan to store inventory.

1. Warehouse Space and Layout

For efficient warehouse operations to be possible, the space and layout of the warehouse must be designed to accommodate maximum efficiency. This includes designating areas for picking, packing, shipping, receiving, returns processing, and employee offices and break rooms.

Our article on streamlining inventory controls discusses the three main warehouse flows more in-depth. But essentially, you’ll need to decide how your warehouse will move products or materials from the receiving area to storage, through order picking and packing, and ultimately, shipping carriers.

2. Automation

Automating certain processes in a warehouse can help reduce errors and speed up the order fulfilment process. These include:

- Picking and packing

- Labelling

- Payment processing

- Returns processing

- Inventory management

All of these processes are highly error-prone and time-consuming if done manually. Automating them can reduce picking error rates by 67% and save a significant amount of time and money.

3. Employee Management

Staff is the backbone of any eCommerce warehousing operation, so it’s important to invest in training and develop a good team culture. This will help ensure that employees are motivated and working efficiently.

Here are a few tips for optimising employee management in a warehouse:

- Develop clear standards and expectations for employees.

- Invest in proper training and safety measures.

- Create accessible training materials and invest in a learning management system.

- Implement a rewards system to incentivise employees and keep morale high.

- Encourage open communication between employees and managers.

- Use team collaboration tools like Slack or Teams to streamline interdepartmental communication.

- Implement performance metrics (i.e., time to complete tasks and accuracy) to track progress.

For optimal eCommerce warehousing, you’ll also need to forecast labour costs and needs. Hiring the right amount of staff is key to providing an efficient and cost-effective service.

4. Security

Security is a critical consideration for any warehouse, especially one handling eCommerce orders. eCommerce businesses need to ensure their warehouses are properly secured with physical and digital security measures to protect against theft or tampering.

CCTV, access control systems, and other surveillance equipment can help you monitor your warehouse around the clock. You should also consider implementing digital security measures like encryption and authentication protocols to protect sensitive customer data.

For the best possible security, it’s best to invest in a cloud-based enterprise building management solution that offers comprehensive security features and mobile access control.

5. Forecasting Demand

Accurately forecasting customer demand is critical to successful eCommerce warehousing. demand forecasting involves using data-driven methods such as sales and customer behaviour analysis to project future demand for your products or services.

Having an accurate forecast helps you optimise stock levels, plan for staffing needs, and minimise risks associated with overstocking, but it’s also impossible without having access to reliable data.

Almost every eCommerce platform (i.e., Shopify, Amazon, BigCommerce, etc.) offers data-driven sales insights to help you make more informed decisions about stocking and staffing, but it is the seller’s responsibility to interpret sales and revenue data in the context of their supply chain.

6. Scalability

As the number of orders and SKUs increases, you’ll need to be able to quickly scale up your warehouse operations to meet customer demand. And if you expand your operations across multiple sales channels, you’ll need to change the way you manage inventory.

This includes expanding storage space, hiring additional staff, and investing in more efficient equipment.

This is one of the trickiest parts of the eCommerce industry in general, as keeping the wrong inventory in stock can lead to unnecessary costs and missed opportunities, while not having enough of the right items could mean lost sales.

Investing in an automated warehouse management system (WMS) is key to scalability. A WMS allows you to manage orders from multiple sources, monitor inventory levels in real time, optimise labour resources, and generate reliable reports.

7. Automation

The eCommerce industry is continuously moving towards greater automation, and this trend extends to warehousing operations as well. Automation can help you streamline your inventory management processes and improve accuracy, resulting in fewer errors and higher customer satisfaction.

Currently, it costs nearly $25 million to fully automate a warehouse, making it out-of-reach for most small- and medium-sized businesses. Fortunately, many vendors offer automated solutions tailored for eCommerce warehouses of different sizes and budgets.

For example, warehouse robots are becoming increasingly popular in the warehousing industry. These autonomous robots can help you automate mundane tasks such as picking, packing, and replenishment with minimal human intervention.

Streamline eCommerce Warehousing With a Warehouse Management System

Whether you run a small online store or a diversified eCommerce business, proper warehouse management includes eCommerce warehousing solutions that reduce costs, minimise errors and help you scale up operations quickly.

The difference between a disorganised operation and a streamlined warehousing process is investing in cloud warehouse management software.

Click here to see how it works, or click here to get started for free.

In my role, I oversee the development of insightful blogs that delve into the intricacies of warehouse management. Each piece reflects my dedication to empowering businesses through informative content. Through my team’s extensive experience in the industry, we aim to bring clarity to the complexities of WMS, helping businesses make informed decisions.

Join me on a journey through the ever-evolving landscape of warehouse technology as we explore the latest trends, industry insights, and practical tips to streamline your operations. Feel free to connect, and let’s embark on a collaborative exploration of how WMS can redefine your business efficiency.

Cheers to innovation, efficiency, and the exciting world of warehouse management!